Dust sometimes appears to not pose a threat to health, safety, and the environment. However, in various industries, from woodworking to manufacturing and construction- its impact is severe and profound.

The presence of dust often results in serious hazards, like respiratory illnesses, causes explosions, accidents, and environmental contamination. These risks have caused the rise of several regulatory bodies to establish rules and guidelines that reduce or eliminate the dangers associated with exposure to dust.

In this article, you will learn about the four main regulatory bodies that formulate and ensure compliance with their set rules and standards to improve dust safety in workplaces and communities. Let’s get into it.

Occupational Safety and Health Administration (OSHA)

Occupational Safety and Health Administration (OSHA), established under the OSHA Act of 1970, a part of the United States Department of Labor, is a body in charge of the safety of workers in healthy working environments. To achieve this, they organize effective training, outreach, and education sessions in OSHA-approved states in the US, ultimately enhancing workplace well-being.

Their coverage includes both private and public sectors in the US. They do not only set laws to be obeyed, they go around the states for investigations and inspections to ascertain organizations comply with the laid down rules, if not, they issue penalties to those who do otherwise.

Manufacturing industries are expected to comply with OSHA regulations governing health and safety workplaces. Of course, their compliance will largely depend on the effective use of dust-capture systems that are aimed at achieving optimal air quality for the workers and the immediate environment. Compliance with OSHA regulations would include the adoption of some of her recommendations and prescriptions that significantly reduce occupational hazards in our work environments. Some of these recommendations include:

Permissible Exposure Limits (PELs) and Threshold Limit Values (TLVs)

To minimize exposure to airborne dust, the OSHA established dust exposure limits for organizations. The PELs as the name implies describe an enforceable standard for the highest allowable concentrations of dust particles that can be inhaled during working hours. Anything outside this limit attracts penalties to employers.

PELs are measured in mg/m³ (milligrams per cubic meter of air) over an 8-hour TWA (Time-Weighted Average). For example, OSHA’s regulations specify PELs of 5mg/m³(TWA) for softwood dust, and 50µg/m³(TWA) for crystalline silica.

The TLVs were set up by the American Conference of Governmental Industrial Hygienists (ACGIH) and serve as a recommended guideline for organizations to also protect employees from dangers to their health while performing their duties. These exposure levels are measured in three main ways, which are:

- TLV-TWA (Time-Weighted Average): For over an 8-hour working experience.

- TLV-STEL (Short-Term Exposure Limit): For a short period, like 15 minutes.

- TLV-C (Ceiling Limit): Should not be exceeded at any time.

TLVs unlike the PELs are not bound by the law, but compliance to both exposure limits provides safety and regulatory compliance. Dust types are one of the considerations in determining exposure limits. The regulations impose stricter limits on silica dust because it poses adverse health risks in contrast to wood dust. The ideal dust hazard for crystalline silica is 29 CFR 1926.1153, while that of wood dust is 29 CFR 1910.1000

Occupational Safety and Health Administration Methods of Dust Exposure Regulation

OSHA uses this hierarchy of controls to manage hazards, including dust in workplaces:

1. Elimination

2. Substitution

3. Engineering controls

4. Administrative controls

5. Personal Protective Equipment (PPE)

Elimination

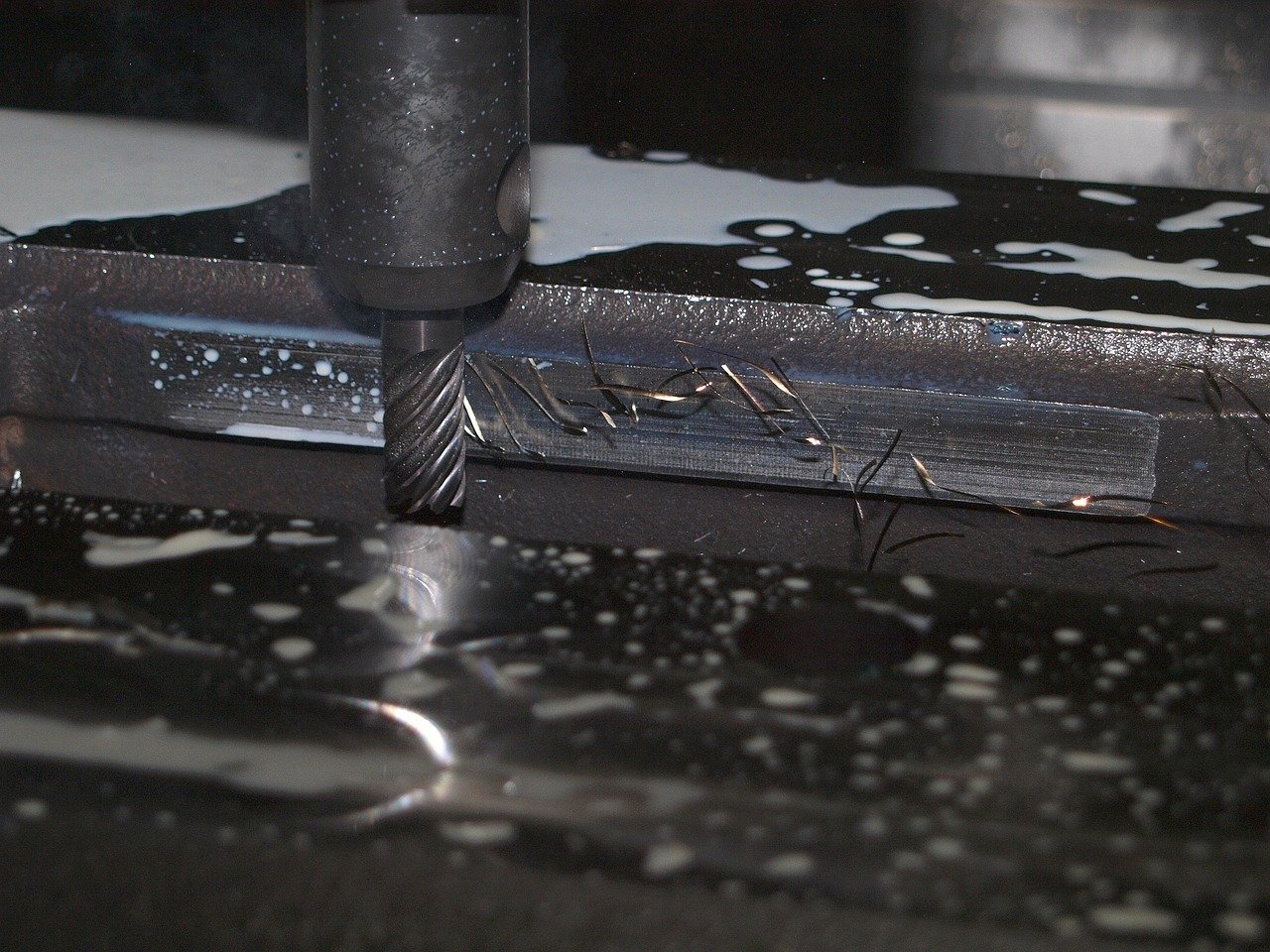

This is considered the most efficient control method in regulating the exposure to dust. It involves eradicating anything that can cause dust hazards or changing equipment or processes used in production. It could be using wet-cutting methods to replace dry-cutting techniques, or using ‘already-made’ materials in place of starting the manufacturing process that generates dust from scratch. In the case where elimination is not attainable, the substitution method should be considered.

Substitution

The substitution procedure requires replacing unsafe materials and dangerous processes with risk-free alternatives. It may involve materials/processes that incur less/non-hazardous dust. A potential option is using non-silica abrasives in place of silica abrasives to reduce vulnerability to silica dust or using water-based coatings as a substitute for powdered coatings.

Engineering Controls

Engineering controls are visible alterations to the materials used or in the workstations to get rid of dust. This approach does not necessarily require any measures from the workers which makes it very effective. The following is a list of engineering control approaches for dust regulations:

- Local Exhaust Ventilation (LEV) – Leveraging ducts, vacuum systems, etc. to trap dust before it gains access to an open workspace.

- Dust Collector Systems- Utilization of advanced technologies like Tysum’s baghouse dust collectors and cartridge dust collectors to evacuate dust from the air.

- Enclosures and Barricades- Building barriers around dust-producing sites to prevent its spread into workstations.

- Wet Techniques – Application of water sprays to reduce the formation of airborne dust.

Administrative Control

This method requires human efforts in its execution, reducing its effectiveness. It involves the organization setting new reforms or modifying their work policies to reduce dust exposure. These new policies can include:

- Reducing the time each worker spends in dusty areas or employing a rotation schedule for workers in different units.

- Introducing training for workers on the dangers of dust and ways to prevent exposure.

- Storage of dusty materials in a closed environment.

- Using vacuum systems while cleaning as an alternative for dry cleaning.

Personal Protective Equipment (PPE)

If all these aforementioned controls are not sufficient, the use of PPE can come into play. PPE is the least effective measure. It only protects the worker wearing it, while the dust hazard affects the environment except when used together with all the other control measures. PPE includes protective clothing like disposable suits, eye protectors, safety goggles, hand gloves, respirators, etc. PPE should be considered as the last control measure in any organization.

OSHA is not only after compliance with their laid down rules and regulations, but also about workers’ efficiency, health, and safety in good working environments. Therefore, it is expedient for employers to conform to, and adopt these safety rules by always assessing the work site for dust threats, venturing into the use of dust control machinery, consistent training programs for workers, and putting effective monitoring systems in place for workers.

These will help reduce work site accidents, and illnesses among employees while promoting a healthy environment for workers and neighboring communities.

National Fire Protection Association (NFPA)

The National Fire Protection Association (NFPA) is a non-profit organization that was established in 1896, and it is a body recognized globally for its dedication to risk reductions associated with hazards like fire, electrical, and other related hazards. It has evolved continually in addressing threats and challenges against fire outbreaks. NFPA is known for its numerous initiatives, the development of certain codes and standards to manage combustible dust hazards, which stands out as a critical focus because combustible dust is not properly controlled; it can amass and ignite, which can lead to catastrophic explosions and cause severe damage to people and properties. If your industry generates dust from wood, chemicals, metal, or plastic, you must consider and take these safety measures by complying with the regulations and protecting your workers and environment.

The NFPA’s Mission and Regulatory Role

The primary mission of the NFPA is to minimize the loss of people’s lives and properties that happen from fire, electrical, and other related hazards. These preventions are achieved by developing codes based on consensus and standards for organizations, conducting extensive research, and by offering training and education about how these hazards can be limited. They work together with industry experts, regulatory agencies, and other important stakeholders to ensure that the guidelines that are established are robust so that they address both long-term and emerging safety concerns.

The standards of NFPA serve as the foundation body that advocates safe practices in a wide range of industries like manufacturing, agriculture, and processing facilities where combustible dust is a significant hazard. The NFPA not only helps in preventing accidents, but it also ensures that facilities maintain a high volume of safety measures, hence protecting workers and assets.

Understanding Combustible Dust Hazards

Combustible dust is fine particulate matter that can ignite and cause explosions when suspended in the air under certain conditions. This phenomenon is not limited to just one industry; it can affect operations in woodworking, chemical manufacturing, metal processing, and food processing, among others. The risk of these dust explosions if not properly controlled is that it can lead to severe accidents at the workplace. For instance, when dust comes in contact with an ignition source, it can lead to flash fire. Dust explosion can occur when airborne dust gets to a certain level and gets ignited. Also, this can post as a health risk for your employees when they inhale fine dust particles, which can lead to respiratory diseases.

To address and control these issues, NFPA has developed strict safety regulations for combustible dust that will help industries prevent disasters by implementing proper dust control measures.

NFPA’s Combustible Dust Standards

To address the risks associated with combustible dust, the NFPA came up with several key standards that guide the design, installation, and maintenance of systems meant to minimize these hazards. These standards help reduce the chance of ignition, but they also provide essential protocols for effective response in a situation when there is an incident.

The NFPA 61 standard is for the prevention of agricultural and food processing facilities. This standard outlines preventive measures that can be taken, proper ventilation that can be implemented, regular cleaning, and the installation of dust collection systems that will minimize the accumulation and dispersion of dust. NFPA 484 is a standard that guides combustible metals like aluminum, titanium, and magnesium. NFPA 664 is a guideline for wood processing plants and for woodworking. The NFPA 654 standard focuses on the prevention of fire and dust explosions in the manufacturing, processing, and handling of combustible particulate solids. While NFPA 660 consolidates the previous standards into a single, unified document. It came into effect in December 2024. This standard streamlines guidelines for the identification, evaluation, and control of combustible dust hazards across various industries, and it emphasizes the importance of performing a Dust Hazard Analysis (DHA) to systematically assess and mitigate risks.

Practical Steps for Compliance

Adhering to NFPA standards is not only a regulatory requirement but also a proactive step toward safeguarding facilities, people, and the environment. These measures can help organizations manage combustible dust risks effectively by conducting a thorough dust hazard analysis. This suggests that performing a detailed Dust Hazard Analysis (DHA) should be the first step toward mitigating hazards that are related to dust. This analysis will evaluate the materials used, the processes involved, and the potential for dust accumulation. When a proper DHA is conducted, it allows businesses to create a workable action plan that aims at reducing dust hazards and incorporates safety measures, such as dust collection systems. Another way to comply with the NFPA regulations is by using an industrial dust collector in your industry. These systems are effective as they capture airborne dust and filter it before it spreads and becomes dangerous to employees and the environment. Dust collectors will help you prevent explosions, improve air quality, and control dust levels in compliance with NFPA standards. And when you are considering choosing a dust collection system, you must know the different industries use different filtration methods depending on the dust type and volume, use high-efficiency filtration filters, and choose to have automatic cleaning features so that filter clogging is prevented.

Also, provision for comprehensive employee training should be conducted, as these regular training sessions and drills, when set in place, will teach employees the risks of combustible dust, help them understand the proper equipment operation and maintenance, and help them handle the disposal of dust safely. When employees are well trained, a safe and NFPA-compliant workspace is effectively maintained.

The processes and materials used in industries may change over time, and this can increase the risks that are associated with combustible dust. This is why it is important that industries periodically review and update their safety measures, upgrade their dust collection systems when needed, be constantly informed about changes in NFPA standards, and work with dust control professionals like Tysum so that safety measures are effectively optimized.

NFPA’s commitment to safety is a model for industries worldwide. When you comply with these NFPA standards, you not only avoid fines, but you will also protect your employees, industrial equipment, and your business from significant dangers of combustible dust. Investing in an industrial dust collection system is one of the best ways to maintain a safe working environment while meeting the NFPA regulations.

Food and Drug Administration (FDA)

Have you ever wondered why the food processing, pharmaceuticals, and cosmetics industries must follow strict air quality and obey certain safety standards? The Food and Drug Administration (FDA) plays a crucial role in setting these regulations that ensure product purity, safe workplaces, and consumers’ health. If your industry uses dust collection systems, compliance with FDA regulations cannot be neglected because they seek to prevent contamination, maintain air quality, and meet set safety standards. When you apply the FDA’s regulations to your industry, it will help you comply and avoid penalties.

Key Responsibilities of the FDA

The Food and Drug Administration (FDA) is a federal agency under the Department of Health and Human Services (HHS) based in the United States (U.S.). It regulates industries such as food processing, pharmaceuticals, medical devices, cosmetics, and dietary supplements. For companies using dust collection systems, meeting FDA air quality and contamination control standards is critical to ensure compliance and product safety.

The FDA plays a significant role like the safety of your food products and air quality regulated to prevent any form of contamination from airborne dust and particulates on food products. Also, pharmaceutical manufacturers are expected to maintain clean environments by setting measures for strict air filtration and dust control. Then, for medical devices, the FDA monitors the safety of the manufacturing processes, and this also includes dust control to protect and promote the integrity of a product. Lastly, in the case of cosmetics and personal care, the FDA oversees airborne contaminants so that unsafe exposure during production is prevented.

FDA Regulations on Dust Control in Food Processing

Preventing Cross-Contamination: Airborne dust and particulates in food and production industries can pose serious health risks to people; hence, the FDA requires that organizations like yours implement effective dust control measures to prevent cross-contamination and to maintain a clean environment.

The Food Safety Modernization Act (FSMA): The FSMA emphasizes preventive measures rather than reactive responses to contamination. Dust collection collectors play a vital role as they capture dust from flour, spice particles, and any other fine food powders that could contaminate products. They prevent combustible dust from building up, which can lead to a fire hazard. Also, they seek to maintain clean airflow and improve the safety of workers in your industry.

Labeling and Compliance: The guidelines of the FDA require that food products be labeled accurately, even with potential contaminants. Industries must put airborne dust under control to prevent having unintended ingredients in their final products.

Dust Control in Pharmaceutical and Medical Device Manufacturing

If you are operating a pharmaceutical manufacturing facility, it is required that you maintain high-efficiency dust collection systems that meet the Good Manufacturing Practices (GMPs). The FDA enforces strict air quality controls on industries to prevent cross-contamination between different drug compounds. They look to reduce airborne particles that could compromise your drug purity. And they seek to maintain compliance with high quality of air and cleanroom standards. Certain pharmaceutical ingredients are potent, and they require containment. Dust collection companies like Tysum produce filtration systems that help you maintain a controlled environment as they capture airborne particles before they spread.

FDA Oversight in Cosmetic Manufacturing

Preventing Airborne Contaminants

Dust collection is critical if your industry produces cosmetic and personal care products where fine powders like talc, mica, and pigments can become airborne contaminants. The FDA requires manufacturers to implement dust collection systems to maintain air quality, prevent contamination of raw materials during production, and ensure proper handling of airborne substances to protect your workers.

Combustible Dust Risks and FDA Compliance

Many types of dust, like flour, sugar, pharmaceutical powders, and dust from cosmetics, are combustible. The FDA requires that you control dust accumulation and implement explosion-proof dust collection systems so that fire hazards caused by airborne particulates can be reduced, safe working environments for your employees can be maintained, and costly facility shutdowns due to non-compliance from businesses can be prevented.

Challenges in FDA-Regulated Dust Collection

One of the first challenges is in meeting volume and efficiency standards. Your dust collector systems must be designed to handle the required air volume while maintaining high filtration efficiency to meet the FDA cleanliness standards. Another challenge is adapting to regulatory changes. FDA regulations are always evolving, as these require industries to upgrade their dust control equipment and implement stricter compliance measures. Also, ensuring proper maintenance can bring about another issue. Regular maintenance of dust collection systems is essential to ensure continued compliance with FDA guidelines. This includes monitoring air quality, replacing filters, and inspecting the systems.

The Food and Drug Administration (FDA) plays a vital role in ensuring air quality, safety, and product purity across multiple industries. By implementing efficient dust control solutions, you can enhance a safe workplace, improve the integrity of your products, and avoid any regulatory penalties. Staying informed about the FDA regulations helps you adapt and uphold the highest safety standards in your operations, as this protects lives and financial investments.

Environmental Protection Agency (EPA)

The EPA is another major environmental agency created to “protect human health and the environment through development and enforcement of regulations”. With its laser focus on air quality management, as its primary assignment, it has its own set of rules, regulations and guidelines propounded to instruct the general public – both private individuals and corporate firms on how to ensure environmental safety, with respect to dust pollution, in their daily, hence overall, activities. Hence, it adopts a stringent preventive control and monitoring pattern.

The then-growing concern on environmental degradation during the mid-20th-century in America, coupled with environmental disasters involving fires like that on the Cuyahoga River, worsening air pollution in major city centers, and the increasing call for federal intervention, by the public, were all and are still relevant indicators that there was a need for a single agency that would unify the various disconnected efforts. A combination of executive orders issued by the then-head of the United States – President Nixon – concretized scattered environmental administrative functions, thus giving rise to the establishment of the EPA. This institution, therefore, has, over its long existence, played roles varying from those of a consensus builder to that of an enforcement power-functioning through CAA-style procedures aimed primarily at combating pollution and promoting sustainability.

EPA’s Systems of Monitoring and Enforcing Compliance with Regulation

Since its inception, the organization has adopted various methods to enforce compliance with all existing air quality standards. Some of these measures include:

- Air Quality Monitoring Stations: Air quality is monitored by the installation of stations across the country. The stations monitor PM levels and present real-time data. By coordinating the local and state authorities, the EPA ensures accurate monitoring and regional compliance with existing standards.

- Permitting and Enforcement: Private industries and facilities that create dust emissions are mandated to work under permits that originate via New Source Review and Prevention of Significant Deterioration. Non-compliance with regulatory performance standards may result in individuals and firms:

- Being fined.

- Having stricter enforcement measures imposed upon them.

- Being shutdown in egregious cases.

With the EPA’s continued existence, confirmation and approval of its productive approach to air quality management, it ensures to catch up with ongoing technological advancements and other technological complications, in recent times, by modifying its approach to contemporary environmental issues. Hence, in addition to its inceptive practices, the EPA has adopted the following practices to ensure continued compliance with air management regulations:

- Proposing more stringent PM2.5 ambient air quality standards based on growing scientific evidence that fine ambient air particulate matter is linked to causing respiratory diseases. These proposals are aimed at lowering health risks associated with this particular particulate and achieving improved air quality in urban areas with high vehicular emissions.

- Partnering with state agencies to develop wildfire smoke management programs, which would include air quality monitoring, health advisories, and emergency protocols.

- Engaging environmental justice programs since marginalized communities bear the burden of air pollution. Not only does this approach begin with community engagement, it also gives these communities the chance of having their own ideas for the purposes of either monitoring or taking back their communities to a cleaner environment.

- Engaging in research and innovations by allocating funds to research into new and unique technologies for controlling dust.

Challenges facing the EPA

Despite the successes and supposed strength we have highlighted so far, the EPA faces its own peculiar set of setbacks. The EPA, like most government parastatals, faces:

- Funding Constraints constrain the EPA’s ability to engage in such monitoring and enforcement of existing regulations. Consequent to this, of course, will be lead to reduction in equipped manpower in the agency, research, and development efforts, which will naturally compromise the EPA’s ability to enforce the relevant regulations.

- The anticipation of pushback on regulations from Industries that are liable to high levels of dust pollution while giving economic reasons to do so. This often puts a strained legal nab between the regulating body and those industries, creating a nab in their enforcement of environmental policies.

- Climate change which leads to dust pollution worsening. The EPA is known for concentrating its efforts on well-founded approaches in addressing these progressive challenges by improving soil stabilization methods and building forecasting models.

Your Practical Tips on How to Comply With EPA Standards

Yes, the EPA is that government agency that is out to ensure the regulation of dust emissions in the environment: but no, its standards are not impossible to comply with. Here are some surefire tips on how you can ensure that you are in compliance with its standards and regulations:

- Understand the regulatory requirements by familiarizing yourself with relevant EPA standards that apply to your immediate region.

- Implementing monitoring systems by establishing on-site air quality monitoring to track particulate matter levels and identify potential compliance risks.

- Obtaining the necessary permits in accordance with regulatory guidelines.

- Adopting environmentally friendly practices that are in line with known regulations.

- Engaging with regulatory authorities such as the EPA and other local environmental agencies to stay informed about policy updates and emerging regulatory requirements.

The EPA plays a crucial role in the regulation of dust and the enforcement of standards for air quality. Through legislation, monitoring, enforcement, research, and public involvement, the agency strives to regulate the effect of dust pollution on human health and the environment, at large.

Along with these lucid duties of the EPA, industries, and individuals have a collaborative role to play to aid the Agency in the noble assignment of dust through empirical practices, clean ways of doing business, and dynamic environmental regulations.

Conclusion

Understanding how these agencies: OSHA, NFPA, FDA, and EPA operate with regard to dust control is crucial in order to operate safely and in compliance with standards. As you have seen, each of these agencies have their unique approach to tackle different aspects of dust hazards, from occupational safety to environmental protection.

At Tysum, where we specialize in the design and fabrication of excellent dust collection systems, we will more than ensure your plant meets these agencies’ standards – we will ensure you excel beyond minimally accepted levels. Partner with us to enhance occupational safety, protect employees’ health, and ensure compliance with environmental requirements.

Don’t gamble with dust control. Reach Tysum today and explore our custom solutions to ensure the compliance, safety, and efficiency of your dust collection system.