Industrial dust collection systems are usually brought in as easy fixes for maintaining air quality, yet beneath the surface lie complex innovations rarely tackled by vendors or plant managers. Based on industry reports and expert analyses, here are the not-so-dirty little facts you need to know:

Underestimated Combustible Dust Risks

Ubiquitous explosion dangers

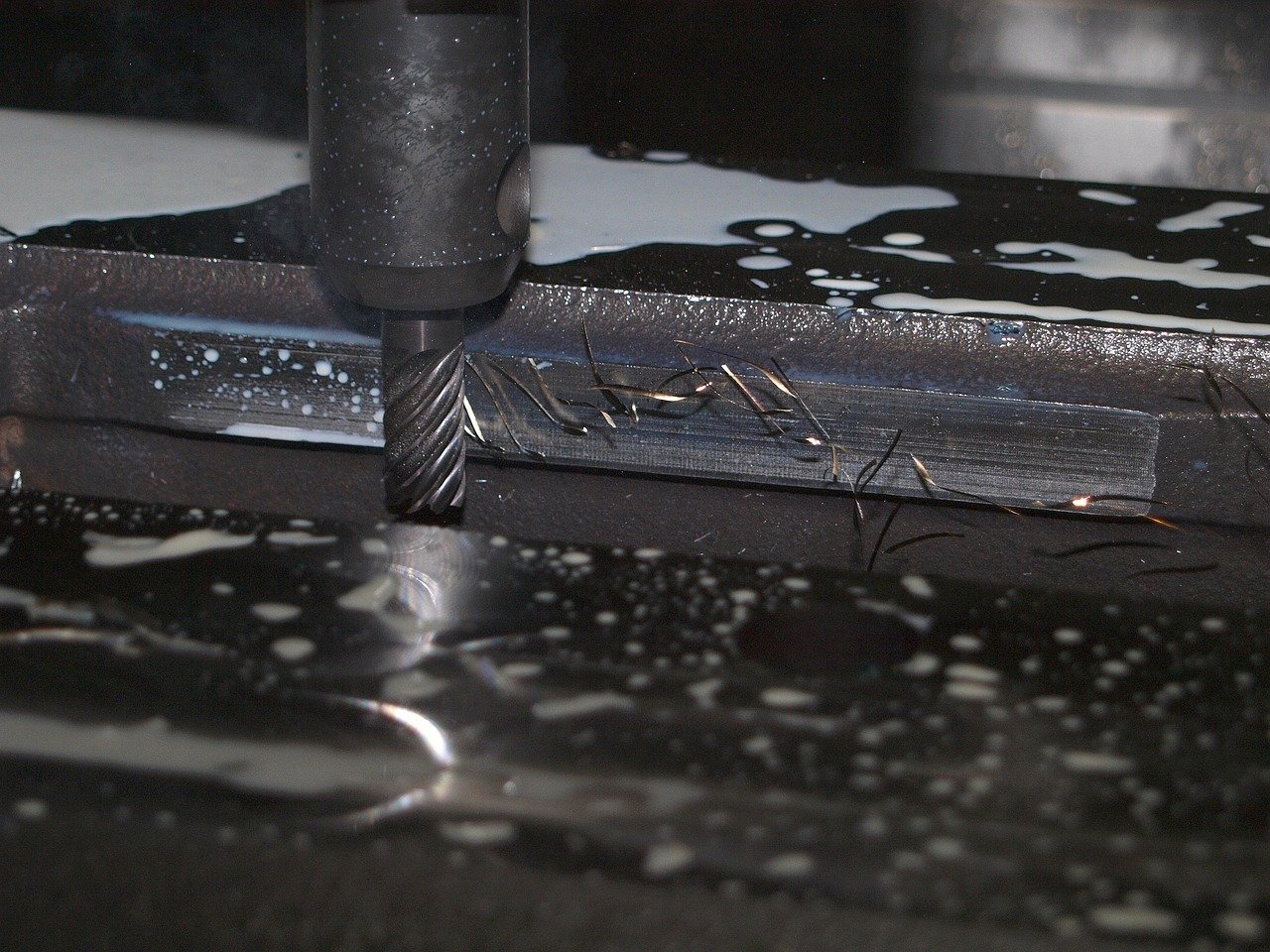

Flammable industrial dust isn’t restricted to apparent industries such as grain milling. Metal fabrication (particularly processes involving aluminum, magnesium, or zinc), pharmaceuticals, 3D printing, and even recycling centers produce explosive dusts that are often underappreciated. Any dust-generating operation must presume combustibility until it is proven otherwise.

Alt: explosion dust

When customizing the industrial dust collection system, you can have a more detailed discussion with your supplier about the production status and dust collection requirements. Professional industrial dust collector suppliers will provide you with a safe and comprehensive solution based on your actual situation.

The “secondary explosion” trap

Whereas the majority of plants attempt to prevent primary explosions in equipment, the silent killer is secondary explosions. Secondary explosions occur when a small initial blast dislodges dust that has built up on beams, ductwork, or ceilings and creates enormous building-wide explosions. A 2020 report indicated 67 dust fires and 11 explosions in just six months in the United States alone.

Particle size illusion

Dust is explosive at diameters which cannot be observed by the naked eye (typically <420 microns). Clearly “minimal” buildup can be very dangerous. A 1/32 inch (0.8 mm) deposit on a mere 5% of a room surface will result in catastrophic explosions.

| Unexpected Dust Sources | Documented Hazards | |

| Automotive Repair | Hexavalent chromium from brake pads, welding fumes | Carcinogenic, explosive |

| Bridge Construction | Metal dust from cutting/grinding, paint pigments | Hexavalent chromium exposure |

| Recycling Facilities | Plastic, paper, and metal dust | Fire/explosion risks |

| HVAC Manufacturing | Metal powders from component production | Combustible metal dust |

Hidden Costs and Maintenance Burdens

Filter replacement fallacy

“Low-maintenance” systems have been found to conceal astronomical filter replacement costs. Vertical cartridge design promote 10% more media and longer life, but abrasive dusts (like silica or metal powders) will decrease filter life by 60% compared with vendor estimates.

Energy secrets

Dust collectors consume 20–40% of a building’s total energy. Pulse-jet units with “energy-efficient” valves still draw massive volumes of air, and ductwork leaks contribute an additional 30–50% to energy cost.

Housekeeping horrors

NFPA 652 requires diligent housekeeping, but many systems create inaccessible areas of dust buildup. Ducts, rafters, and equipment tops become “dust reservoirs” requiring specialized cleaning equipment and confined-space entry techniques.

Overlooked Design and Performance Bugs

Airflow misalignment

70% of underperforming systems are caused by improper airflow design. Hood placement >6 inches from dust sources can reduce capture efficiency by 90%. Duct elbows and unnecessary length add resistance, rendering systems ineffective.

Filter mismatch hazards

Wood dust filters on metal dust applications are a disaster waiting to happen. Hexavalent chromium (from stainless steel processing) requires HEPA filtration, and explosive dusts require flame-retardant media. Most vendors provide one-size-fits-all solutions.

The “indoor installation” blind spot

Indoor dust collectors require flameless vents and explosion isolation valves—equipment often omitted to reduce costs. Without them, a collector explosion vents flame into the workplace, triggering secondary explosions.

Alt: Indoor installation of dust collection system

Compliance Gaps and Regulatory Pitfalls

DHA (Dust Hazard Analysis) shortcomings

NFPA 652 mandates DHAs, but in practice, they are done as documentation. True DHA entails testing explosibility of the dust (Kst, Pmax values), identifying hidden areas of accumulation, and evaluating ignition sources like static electricity due to poorly grounded ducts.

Spark arrestor procrastination

Spark arrestor lag is the source of 38% of dust collector fires. Unprotected, routine dust collectors are akin to bomb-like enclosures when processing hot materials (e.g., welding fumes or grinding sparks).

Ventilation synergy failures

Dust collectors do not have the capacity to process toxic gases like hexavalent chromium. Plants need combined local exhaust ventilation (LEV), yet only 20% of them properly install LEV at emission sources.

Vendor Oversights and Emerging Challenges

Myths regarding AI/ML deployment

Even if AI-driven dust monitoring systems are able to predict danger, they require gigantic sensor networks and calibration of data. Plants are not designed in general to maintain them, generating false security.

Nanomaterial blind spots

Particulate dust collectors used for traditional particulates won’t work with nanoparticles from emerging materials (e.g., carbon nanotubes). They escape ordinary filters, introducing new respiratory risks.

Maintenance dependency

The “15-year warranties” still require quarterly maintenance, differential pressure testing, and duct cleaning—services commonly sold in costly annual agreements.

Conclusion

The most lethal myth in industrial dust collection is that systems are “install and forget” solutions. They are, in fact, dynamic safety systems that require constant attention, comprehensive engineering, and cultural commitment to safety. By embracing these unspoken complexities, facilities can transform dust management from a compliance requirement into a pillar of operational resilience. You can contact Tysum to get a turn-key solution.