CNC machines are used to create complex components and parts by removing material to form the desired shape. Due to its task, it generates large volumes of dust particles that can endanger the equipment and workers when left to spread. For proper dust management, facilities must install CNC dust collection systems.

This article will dive into how dust particles from CNC machines can affect the industry, and how dust collectors can address the concern.

Impact of Dust from CNC Machines

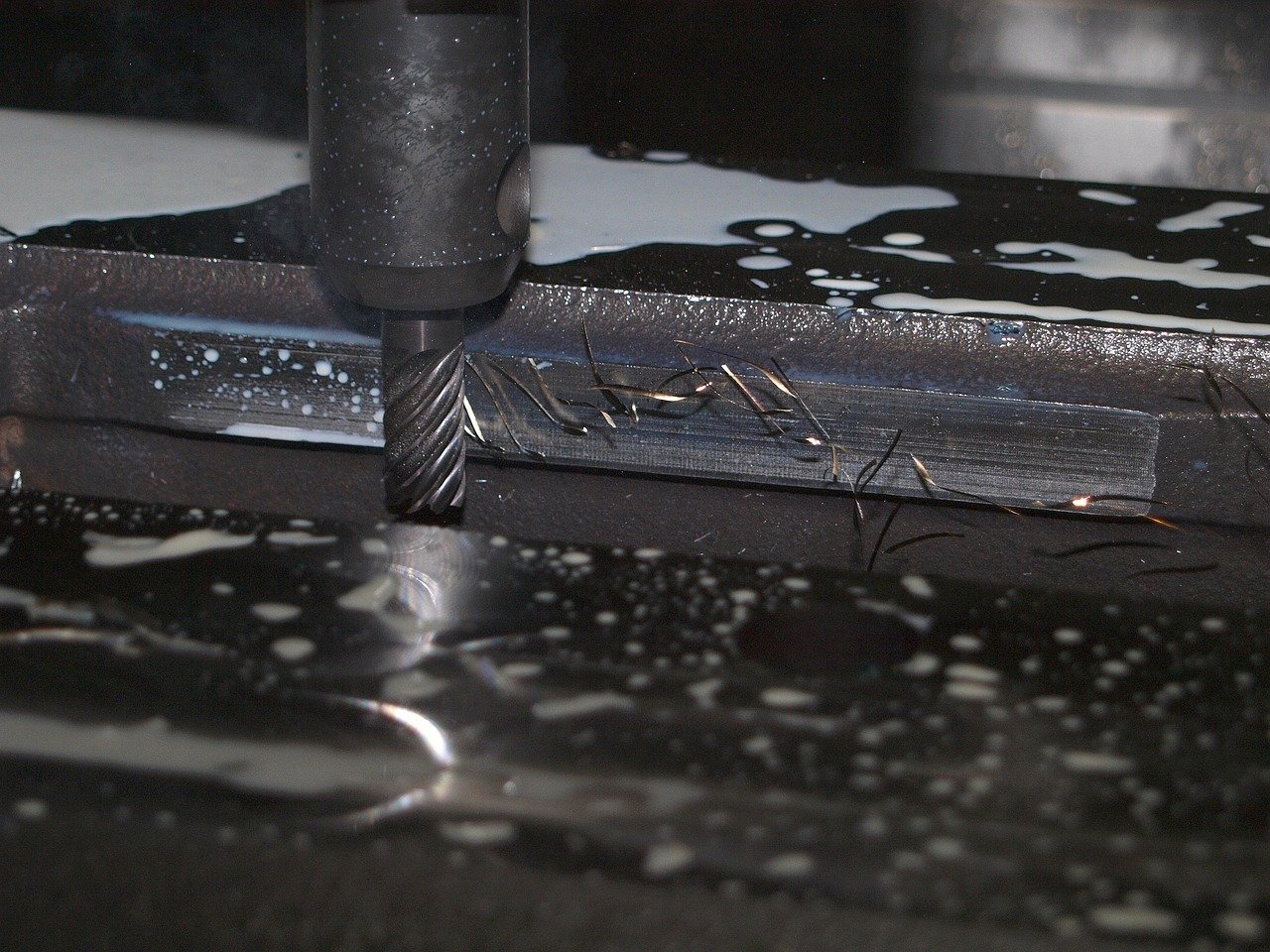

Source: Pixabay

Before selecting the right dust collector for a CNC machine, it’s crucial to understand why one is needed for the equipment. Understanding the risk posed by dust particles that CNC machines generate will provide a good direction as to what kind of dust collector can handle the task.

Risk to the Workers

Dust particles from CNC machines contain toxic compounds that can negatively affect the physical condition of workers who are constantly exposed to them. When inhaled, they can enter the worker’s lungs, which could lead to respiratory problems like asthma, chronic bronchitis, or hypersensitivity pneumonitis. Moreover, direct contact with the particles will trigger allergic reactions like skin irritation, inhibiting their well-being and performance.

Risk to the Equipment

Along with the toxic compounds that can harm the worker’s body, these dust particles can also harm the performance and longevity of your CNC equipment. Left unchecked, the particles can enter the machine’s vents and open spaces, which can cause increased wear or overheating. Additionally, the compounds within the particles are highly combustible, which can explode when ignited.

Risk to the Environment

Another concern includes the potential harm these dust particles can cause to the environment once they escape the facility. The dust particles can linger in the air for long periods, polluting the air in surrounding areas. Plus, the toxins within the dust particles can include formaldehyde, a known carcinogen that directly leads to the development of cancer cells.

Industry Challenges

Despite the desire to manage the dust particles, the industry faces several obstacles in handling CNC dust collection. The concern comes from several factors, which require identification to properly address the problem. Some main pain points include:

Equipment Challenges

CNC machines have several moving parts to perform their task. As such, trapping the dust particles from the source can be challenging for those managing the workshops. There’s also the issue of automatic tool changers or ATCs requiring more space, thus placing the dust collector far from the machine.

Operational Obstacles

To properly manage dust accumulation in facilities that use CNC machines, regular cleaning of the machines and vents is required. Constant downtimes for cleaning can affect the facility’s overall performance, as it eats through the production timeline.

Not only that, but some CNC dust collection systems can also be quite loud when operating, adding to the noise produced by the facility. This can hinder the performance of the workers, resulting in a drop in the facility’s output.

Material Concerns

Different materials produce different types of dust, each with components that may require specific solutions to address. Wood dust, for instance, is lighter and more abrasive, while metal dust may have resins or toxins. And if the workshop handles several materials at once, then dust control can be more challenging, as several dust management filters will be needed.

Dust Collection in the CNC Application

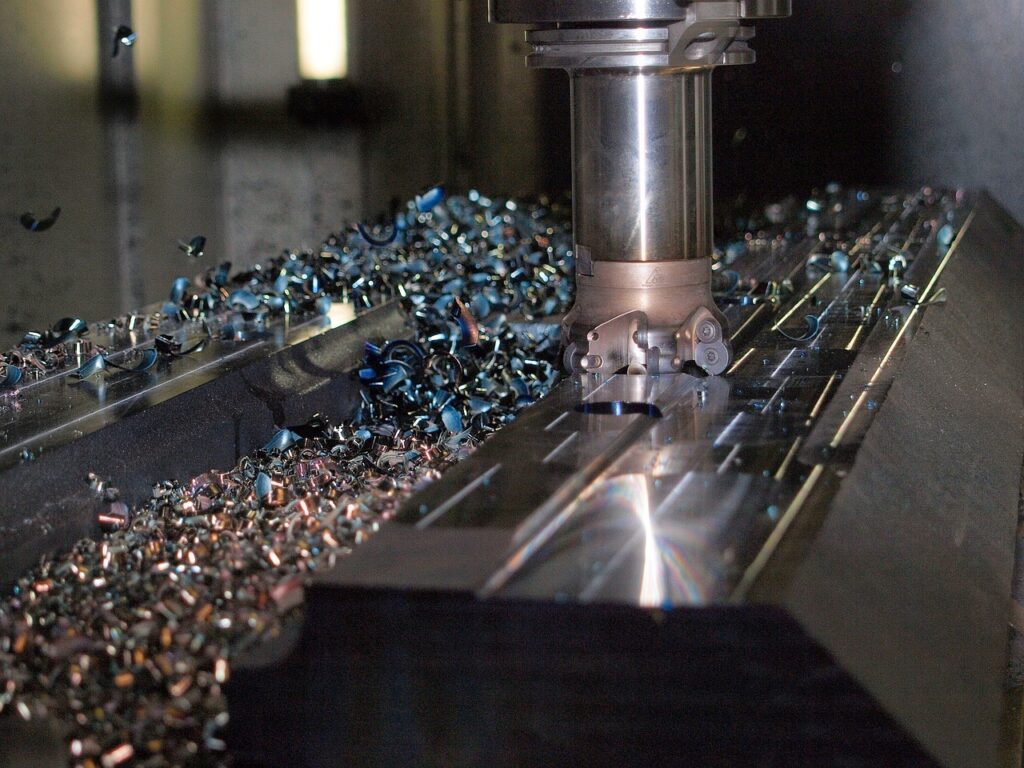

Source: Pixabay

With all the harm that dust particles from CNC machines bring, facilities need to secure a reliable dust collection system. Preferably, the best dust collector for a CNC router should be capable of drawing out the dust particles as close to the source as possible. This ensures that the particles won’t spread throughout the facility and harm the machines and workers.

CNC dust collector systems come in two main varieties: portable and stationary types of dust collectors. Portable dust collectors can easily be moved from one workstation to another and usually come with hoses for direct dust collection. However, these types have a limited dust collection capacity and air flow levels.

On the other hand, stationary dust collectors have a wider air flow range and filtration capacity. They draw out the dust-filled air through the facility’s various exhaust vents and return the clean air into the workstations, improving air quality. However, it does require a significant investment in space and installation.

Benefits of Properly Managing Dust Particles in CNC Machining

- Extend Machine Lifespan – Fewer dust particles entering the CNC machine reduces the risk of the equipment overheating and deteriorating. With crucial parts like motors, gears, and cooling systems protected from harmful dust, there’s less downtime and lower maintenance costs.

- Improve Production Performance – Along with affecting the equipment, the buildup of dust particles can also influence the accuracy of each cut. More so if the machines are working on parts that require tight tolerances. This will elevate the quality of each machined part, reduce error rates, and shorten manufacturing cycles.

- Cultivates Safer Workplace Environment – Controlling the spread of harmful dust particles also protects the health and safety of the workers within the workshops. Less dust lingering in the air means lower risk of contact, resulting in healthier and stronger personnel. Additionally, this helps the facility maintain operating standards set by governing bodies like OSHA.

How to Select the Best Dust Collectors for the CNC Industry

To help you in sourcing the best dust collector for CNC router, we’ve streamlined the process in four simple steps.

Assess Machine Size

First, check the type of CNC router your facility is using. Remember that the more powerful the machine is, the more dust it tends to generate. Hence, knowing the dimensions and capacity of your CNC machine will make your sourcing more efficient.

Determine the Type of Dust Generated

Next, understand what kind of dust particles your CNC workshop is producing. Different types of materials create certain dust particles and will require specific filtration media to handle the dust. Wood dust, for example, is light and abrasive, meaning the filters must be durable enough to prevent them from breaking.

Compute Airflow Requirements

Another point of consideration is computing the airflow needed to facilitate the proper movement of dust-filled air into the dust collector. To get the CFM, simply multiply the facility or workshop area by the airspeed needed.

Choose the Best Dust Collector for CNC Router

After getting these details, it’s time to determine what kind of dust collector you should have for the facility. For smaller workshops, portable dust collectors work best. But for larger facilities and multiple workshops, then stationary dust collections can do the job better.

Moreover, you can also choose between baghouse or cartridge-type dust collectors. Cartridge dust collectors are ideal for fine, flowing dust particles, while baghouse dust collectors can handle sticky or oily dust particles with ease.

Tysum Dust Collection Solutions for the CNC Industry

Source: Tysum

For CNC dust collection that businesses can rely on, source it from Tysum. Spearheading the air filtration industry for more than two decades, we’re leaders in creating optimized and cost-effective dust collector for CNC machine. Whether you need baghouse or cartridge dust collectors, we have the appropriate filters and filter media for your market’s needs.

Along with our commitment to providing dependable dust collectors, we can also manufacture custom air filtration systems tailored to the facility’s requirements. All dust collectors are produced from scratch in our ISO-certified facilities spread across China, ensuring fast production without compromising quality and performance.

Cartridge Dust Collectors TSLT-8L

Made from the finest raw materials, the TSLT-8L cartridge dust collector is engineered for maximum efficiency. The setup has a filtration efficiency of rate of 99.9% for fine dust particles, allowing for optimal air flow management and low pressure drops. These dust collectors are particularly designed for workshops that use CNC machines, like woodworking and grinding.

Cleaner, Dust-Free CNC Machine Workshops with Dust Collectors

Dust management is a regular concern in the CNC industry. As such, dust collectors are vital for maintaining ideal production levels in CNC machining facilities, as they eliminate dust-filled air and replace it with clean air. Not only does it protect the equipment from breakdowns or overheating, but dust collectors also help protect the health and well-being of the workers.

Knowing how to select the right dust collector for your facility will make your investment worth every penny. It streamlines the sourcing process by consolidating your facility’s needs and aligning them with the right dust collector.

Contact Tysum today for your CNC machine dust collector needs. Our experts are ready to assist you and provide expert recommendations through a free consultation.