When it comes to air management in production facilities, fume and dust extractors are an integral part of the discussion. And since these pieces of equipment require a significant investment, it’s equally important to know which one to procure to match the facility’s needs. We’re here to help you understand the characteristics of fume and dust collectors, helping you make the right purchase.

Differences Between Dust Collector vs Fume Extractor

Before we proceed, let’s answer one of the most important questions about the topic: what separates a fume extractor from a dust collector? Knowing the difference between a fume and dust extractor can not only save your business from unnecessary expenses but also ensure your facility gets the filtration equipment it needs.

One thing to consider is that not all fume extractors can be used as dust collectors, and vice versa. While some variations can do the work of the other machine, others may require specific setups or modifications to accommodate both tasks in a single setup. The table below will point out some key differences between a fume extractor from a dust collector.

| Fume Extractor | Dust Collector | |

| Main Function | Draws out toxic fumes and gases generated during production | Collects dust particles in the air and removes them from the facility |

| Filtration method | High-efficiency filters deal with harmful fumes and gases in the air stream | Uses bags and cartridges to separate the dust particles from the air |

| Space requirement | Small and compact design makes it easy to move around the production workshop | Due to the centralized setup, it requires a dedicated space in the facility to install and operate |

| Capacity | Works in a localized area, typically placed in close proximity to the machine generating the fumes | Can handle larger spaces with ease, from several workshops to the entire production facility |

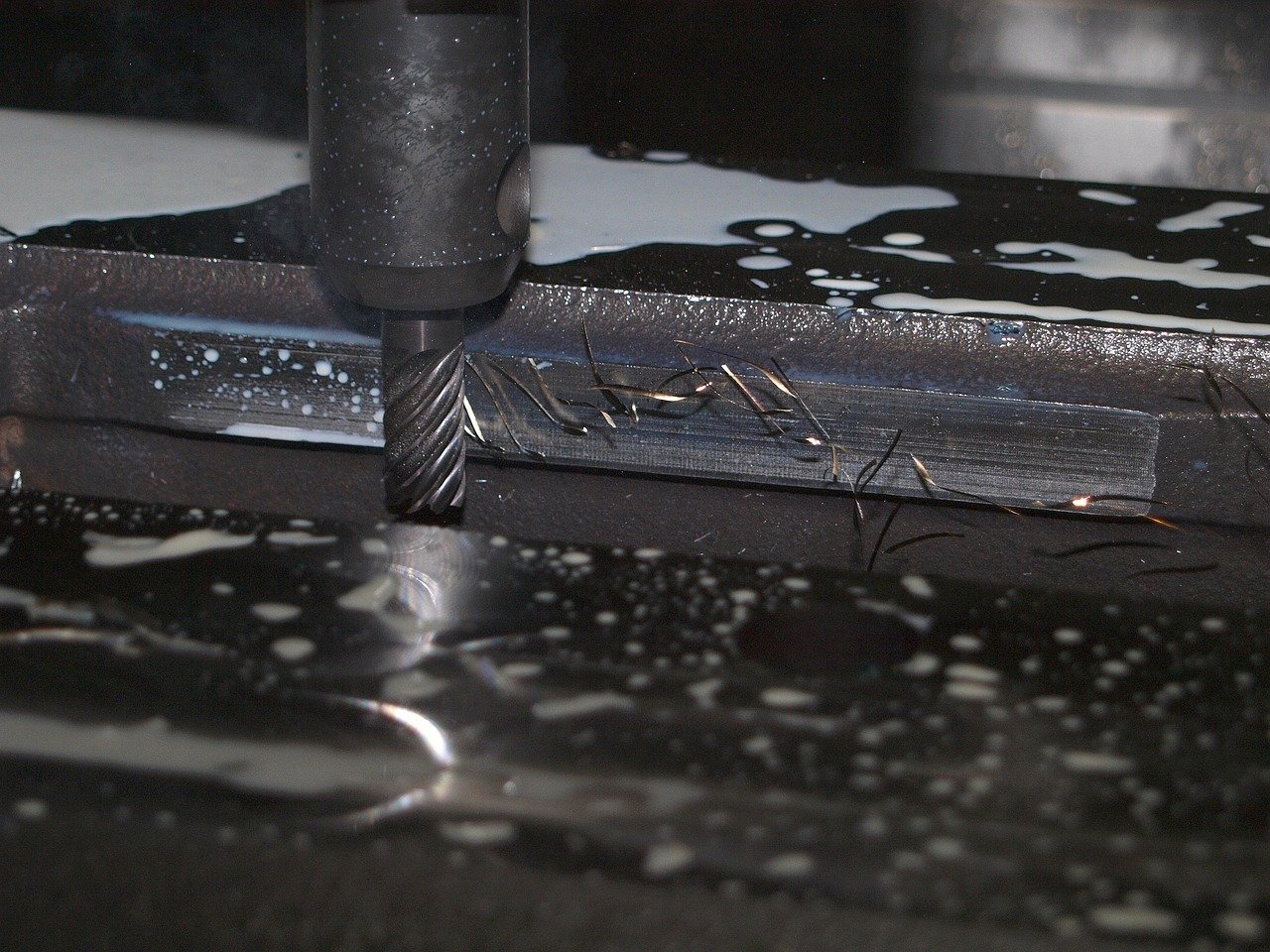

| Use Cases | Typically used in workshops that deal with welding, soldering, polishing, metal cutting, and grinding | Along with general dust removal in shops, these are ideal for woodworking and CNC machining workshops |

| Budget | Price mainly depends on performance and efficiency capabilities | High initial cost due to equipment production and installation; requires replacement bags and cartridges |

What is a Fume Extractor?

Fume extractors are filtration units designed and manufactured to control the spread of harmful gases produced by production facilities. More than an exhaust fan, this machine uses high-powered suction vents to draw in toxic fumes, trapping the contaminants, and returns the filtered air to the workshop.

Typically compact in design, they can easily be placed near the machines that generate the contaminated fumes to draw out the gas as close to the source as possible. Fume extractors also come with hoses that allow direct suction from any position.

How it Works

- The machine is placed near the machine that generates toxic fumes.

- Once in operation, the fume extractor draws the contaminated gas from the equipment using powerful fans and flexible hoses.

- Upon entering the machine, the fumes go through the filtration system, separating the harmful particles from the air.

- The cleaned air is then pushed back to the workshop, promoting better and cleaner air circulation.

Key Applications

Facilities that generate high volumes of toxic fumes should have fume extractors included in their setups. These would include:

- Metalworking workshops, specifically for welding, grinding, and soldering

- Workshops that handle potentially toxic chemicals, like chemical processing and painting

- Spaces where materials are burned, like laser engraving and etching workshops

Benefits of Using a Fume Extractor

Portability – thanks to the compact design of fume extractors, they can easily be moved from one end of the workshop to another. The addition of flexible hoses allows for direct fume extraction, reducing the risk of these harmful gases from spreading.

Healthier Work Environment – with less harmful gases and fumes circulating in the facility, workers are less likely to be exposed to toxins that can affect their bodies. The improved air quality also boosts morale, securing the safety and comfort of the workers.

Better Production Output – as workers experience better working conditions, they’re able to work on projects more and have more personnel available in the facility. This translates to faster production cycles, resulting in higher output with consistent quality.

What is a Dust Collector?

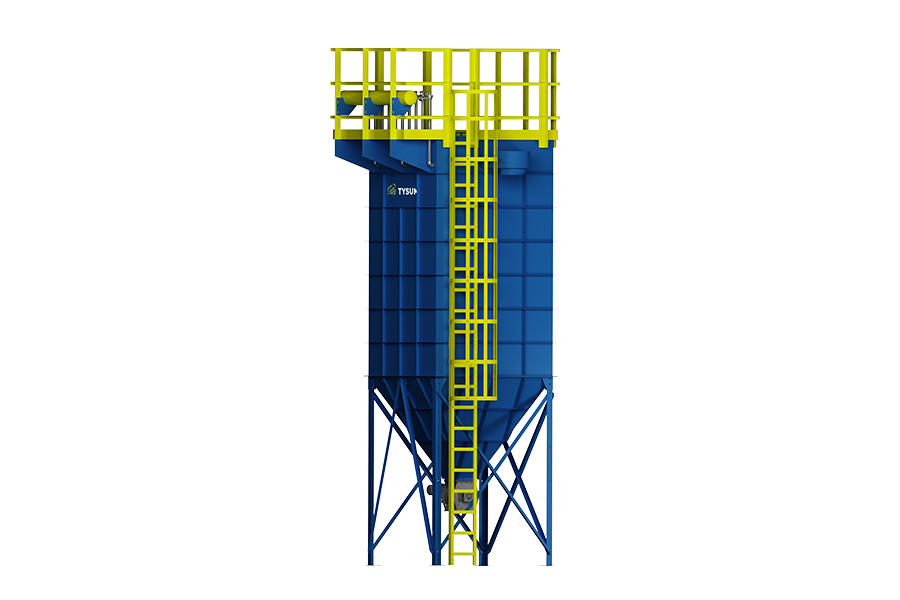

Dust collectors are industrial air filtration systems that separate dust particles that contaminate the air of production facilities. Typically large and requiring significant space and installation, dust collectors utilize the factory’s ventilation system to draw in dust-filled air and return the clean air into the workshop.

These dust collection setups come in different variations depending on the factory’s needs, including particle size and abrasion type. The most popular are baghouse dust collectors that use large bags to filter the air and cartridge dust collectors that have cartridges to draw finer dust particles.

How it Works:

- Dust collectors draw the dust-filled air through the various vents in the workshop.

- Dust particles are separated from the air as it passes through the air filters, with the particles remaining on the filters.

- Clean air is circulated back into the facility, while the dust particles are sent to the retrieval section for disposal or recycling.

Key Applications:

Dust collectors are best used in workshops that generate large volumes of dust particles. Industries that require dust collection setups include:

- Businesses with large workshops, as dust collectors can cover a larger area and integrate well with existing ventilation systems.

- Facilities that produce abrasive dust particles, such as woodworking workshops.

- Food processing and pharmaceutical plants, since they are susceptible to cross-contamination through dust particles, leading to product recalls and lost sales.

Benefits of Using a Dust Collector:

Cleaner, safer air – with dust collectors installed in the facility, minimal dust particles roam in the air stream. This promotes a better air quality that will reduce the risk for employees working in these workshops.

Centralized setup – as dust collectors utilize the facility’s existing ventilation system, it can cover a wider range and guarantee every inch is free from dust particles. It also saves on procuring multiple equipment for dust control and air filtration.

Longer Equipment Lifespan – dust particles that stay in the air can get stuck on the facility’s equipment, leading to equipment breakdown or overheating. With dust collectors, these particles have no chance to enter the equipment, keeping them clean and safe.

Tysum – Leading Dust Collector Manufacturer in China

Tysum is your partner in promoting clean and safe work environments through reliable dust collection systems. Serving various facilities worldwide for more than two decades, we offer a wide assortment of air filtration solutions specifically designed to address your market’s demands. From baghouse dust collectors that can handle abrasive materials to cartridge dust collectors for fine particles, we have the equipment and filters to get the job done.

Along with our standard line of products, we can also customize our dust collection systems to create bespoke solutions for any facility. Our commitment to top-level production is backed up by five factories located across China, ensuring fast sourcing and manufacturing. We also adopt the latest in dust collection technology, utilizing cutting-edge components to make our dust collectors perform at the highest level.

In addition, we also provide exceptional service throughout your sourcing experience, with dedicated project managers handling your project from day one. Our expert support team will also be ready to answer all concerns after order fulfillment, making sure you get top-notch support at all times.

Clear Distinctions Make Sourcing Dust Collectors and Fume Extractors Easier

Fume and dust extractors play a vital role in maintaining the optimal condition of any production facility. More than just cleaning the air, these filtration machines ensure the safety of the workers and functionality of the facility equipment. Knowing the difference between the two types of filtration machines will guarantee that you’ll be getting the right ones for the task.

When sourcing your next dust collector, make sure you’re getting it from Tysum. We manufacture a range of dust collection systems that can be modified to match specific market needs. Book your free consultation today to learn how we can turn your ideas into reality.