No matter the industry your facility is in, industrial dust is a concern that factories worldwide have to manage. As such, industrial dust collectors play a significant role in maintaining optimal performance in any manufacturing plant.

In this article, we’ll break down everything you need to know when shopping for an industrial dust collector. We’ll also go through the details of each important factor for the selection process, from learning about industrial dust to choosing between baghouse and cartridge dust collectors.

Understanding the Industrial Dust

The first, and possibly one of the most important things in choosing an industrial dust collector, is knowing what dust your facility is producing. You’ll be investing a lot in sourcing an air filtration system, so it should properly complement your facility’s specific needs. The last thing you’d want is to spend time, money, and space on an industrial dust collector that can’t handle the particles, leading to potential concerns within the factory.

Here are some major points to factor in when choosing your industrial dust collector:

- Air flow – the air flow conditions, like the temperature and whether the air flow goes out, need meticulous inspection.

- Combustibility – some dust particles can be explosive when introduced to heat or pressure, like aluminum dust or wood dust. If the dust is combustible, consider whether installing a wet system makes the concern easier or riskier to manage.

- Chemical composition – depending on its source, dust particles have specific chemical compositions. Metal dust, wood chips, plastic particles, and polishing fluid residue contain different materials, which will determine the chemical compatibility of your setup. It will also be the basis of what kind of filter material best matches your air filtration system.

- Particle size – while undetectable by the naked eye, dust particles come in an assortment of sizes. Smaller dust particles may require high-frequency filters like HEPA filters to separate the dust from the air. For larger particles, cyclone separators work best in taking the dust out of the air stream.

Dust Recycling and Disposal

Another point to consider under this category is whether the dust will be reused or will it go directly to disposal. Having a concrete answer to this will determine part of your dust collector’s overall setup, including the addition of specific equipment to facilitate the recycling or disposal process.

Interestingly, some dust particles can be recycled for other processes, like cement kiln dust for removing chlorine, potassium, and other elements. If the dust particles your facility generates can be recycled, you need to look into the process required for recycling. You’ll also need to know if the dust particles can be used wet or should be completely dry upon processing.

Conversely, discharging dust particles also requires some consideration to avoid any complications. One of these is the additional cost of disposing of the type of dust particles your factory is producing.

Potential Contamination

Then, you’ll have to know if the dust particles generated by the facility have contaminants you should be aware of. Most contaminants can be harmful not only to the environment but also to the personnel working within the facility. Properly assessing the kind of contaminants, along with how they can affect personnel and nature, can help with the dust collector selection process.

Some points to consider include:

- The type of contaminant the dust particles have, like oil mist, moisture, or volatile organic compounds (VOCs).

- The water solubility of these contaminants

- The adverse effects of the contaminants on humans and the environment

Do note that you may need specific equipment based on the type of contaminant the dust particles contain. Additional ventilation or chemical treatment plants are some machinery you’ll require to efficiently handle these contaminants.

Dust Generation Volume & Dust Collection Needs

The level of dust particles the facility creates on a regular basis is another crucial factor for determining the type of dust collector required. Learning more about this will be our next step in the air filtration system selection process.

Why, you ask? Here’ the deal: not all manufacturing plants generate the same volume of dust – some factories create more dust particles than others. And as dust collectors have specific load capacities, not matching the dust volume with the air filtration system’s operating power may lead to inadequate filtering.

There are three main factors to look at here. Let’s dig deeper into these items and understand how to gather the needed information.

Dust volume

Dust volume refers to how much dust a facility generates in a specific interval, usually looked at either per hour or per day. This directly influences the capacity of your air filtration system and air volume design.

For example, a specific room may generate several pounds of fine dust an hour. You’ll need a dust collector that can draw out the dust from that room and promote better air circulation, thus elevating the air quality.

- First, determine the mass of the dust your factory is dealing with. It’s best to use a precise measuring tool to get accurate numbers.

- Next, get the density of the dust material through a thorough laboratory analysis.

- With the details on hand, compute the dust volume using the following formula: Volume = Mass / Density. The result will be the dust volume for your facility.

Production frequency

Dust particles occur during a facility’s operating hours. Thus, it’s vital to factor this in when choosing a dust collection system, as it ensures the proper air quality, equipment safety, and overall personnel health. Additionally, having the production frequency of your facility will determine the operating load of your air filtration system, along with the durability requirements.

Some details you’ll need to provide are how frequently the facility generates dust particles, whether it’s continuous or intermittent. Keep in mind that the longer the production hours are, the more dust particles your plant produces. For instance, 24-hour production lines will need dust collectors that can seamlessly operate with minimal downtimes.

Number of dust-generating equipment

Each equipment generating dust adds to the total dust particles circulating in the air, which your dust collection system will need to filter. As such, you need to consider how many dust-generating particles are in your factory when shopping for your air filtration system.

The number of polishers, cutters, and other dust-generating machines your plant uses will also determine whether to design a centralized or decentralized system. Centralized systems handle dust from multiple workshops at once, while decentralized systems work independently for better flexibility.

Factory Layout and Space Limitations

Installing an air filtration system for a facility requires careful planning and strategic placement to ensure optimal dust filtration and maintain excellent air quality. In this section, let’s look at some details you’ll need to factor in in choosing the dust collector for your factory in terms of location and layout.

Equipment distribution

The first item on this list involves the facility having enough space for the air filtration system. Industrial dust collectors require significant space for installation, as the entire setup can be quite large to properly filter and collect dust particles in a factory. Plus, the setup has multiple pieces to facilitate the air filtration process, including dust collection ducts and collection points spread throughout the plant.

Alongside allotting a specific location for the main dust collection equipment, it’s also important to pinpoint where and how much dust-generating equipment there is in the facility. This will help determine the design of your dust collectors and how the setup will be installed upon arrival, as stronger dust collectors need to be placed in dust-concentrated areas.

Workshop Space

Then, we also need to look at the exact dimensions of the production space where the dust collector setup will be installed. This would include the size and height of every workshop, as well as all existing ventilation facilities and their capacity.

Moreover, your air filtration system must adapt to the factory’s working conditions to efficiently collect the dust and improve its conditions. As such, determining the dimensions of every workshop will help in selecting how many dust collectors and fans must be installed per workshop.

Piping design

Now, you may be wondering why a floor plan is needed for the dust collector system installation. The facility’s floor plan provides a layout of where everything is placed, including ventilation pipes, foundation, and the like.

Giving your air filtration setup manufacturer the current floor plan of the facility will help them optimize piping lengths and routing plans. This guarantees that pressure losses and dead legs are avoided during operation, which could result in a drastic drop in performance.

Working Environment and Operating Conditions

Your dust collection system must seamlessly complement the factory’s environment to enhance its conditions while minimizing distractions or downtime. Here are some points to look at to ensure that the air filtration setup will be a perfect fit for the facility.

Cleanliness Requirements

Each facility has specific air quality standards to uphold, such as a cleanroom ISO rating, depending on the industry it is catering to. Cleanliness in production facilities ensures that workshops are devoid of any dust particles that can contaminate or affect the final quality of their completed products.

An example of this is optical component plants, where workshops require extremely low particle concentrations to continue operations. Additionally, production plants for the pharmaceutical and food industries have minimal tolerances for floating dust particles, as it can lead to contamination and potential recalls.

Temperature and Humidity

Next, we have to consider the temperature levels within the workshops, as well as humidity and condensation conditions during production hours. These factors will be used in selecting the materials to use in creating the dust collectors, as they have to complement the working environment of their designated workshops. If needed, the dust collectors can also be equipped with corrosion-resistant properties to withstand extreme conditions.

Noise Control

One thing about dust collectors is that they can be loud when in use, particularly due to the fans that create the airflow and vibrations. And similar to cleanliness, certain facilities have noise control levels to manage according to their industry’s standards. High levels of noise during production can affect worker health and decrease productivity when left unchecked.

Thus, your dust collector manufacturer needs to know if you have to maintain a certain level of noise during operations. If the air filtration system you need doesn’t match the noise level requirements, they can install a silencer for quiet operation, accommodating facility standards.

Regulatory and Safety Requirements

Next in the dust collector selection process is making sure that it matches the regulatory and safety standards set by your specific industry. Each regulating body has its specific rules that facilities have to adhere to, and your industrial dust collector manufacturer should help you comply with these metrics.

OSHA

The Occupational Safety and Health Administration, or OSHA, is the government agency responsible for maintaining safe and healthy working conditions throughout the United States. The agency enforces safety standards in the workplace, provides facilities with proper training and education, conducts routine inspections to ensure adherence, and investigates accidents related to the workplace.

Some of the key metrics they strictly monitor are:

- Permissible Exposure Limits (PELs) – refer to the legal limit that employees can be exposed to a concentration of substances without the health risks. For example, PEL for silica is 50µg/m³ per OSHA standards.

- Filtration Efficiency – relates to the capability of a filter can remove dust particles from the air stream. OSHA requires filter media to have 99% filtration efficiency to meet their standards.

EPA

The Environmental Protection Agency, or EPA, is another federal agency in the US assigned to protect both human life and nature. They spearhead the development of and enforcement of regulations aligned with environmental protection while assisting with eco-centric programs.

Some of the key metrics the EPA enforces include:

- Particulate Matter Emissions (PM Emissions) – refers to dust particulates that are released into the atmosphere. When inhaled, these particles may lead to serious health risks for employees and the residents around the facility. The EPA requires 12 µg/m³ for PM2.5 or particles smaller than 2.5 micrometers.

- Hazardous Air Pollutants (HAPs) – also referred to as air toxics or air pollutants, the EPA strictly regulates the exposure to some materials due to causing health concerns like cancer. For lead, the EPA enforces 0.15 µg/m³.

NFPA

The National Fire Protection Association is a global non-profit committed to eliminating any injury, death, property damage, and economic loss related to fire and electrical hazards. They publish numerous codes aimed at fire and electrical safety, which facilities should follow to stay in business.

Some of the codes the NFPA drafted and enforced over the years include:

- Explosion Protection – the NFPA 69-2019 sets guidelines pertaining to systems that will prevent explosions in enclosed locations with flammable materials, including dust particles.

- Dust Classifications – along with several codes, the NFPA has classified dust particles based on their combustibility using parameters like the dust deflagration index or Kst. NFPA has set a Kst value of 200-300 bar-m/s for metal dust.

Industry-Specific Needs

A great thing about working with a specialized air filtration system manufacturer is that you can develop a custom dust collector specifically designed for your business. From the dimensions and material of the dust collector to the type of filter media to handle the generated dust, they can design and produce the equipment to your specifications.

Industry specificity

Different industries produce a type of dust that they need to control, thus having different air filtration requirements to address their concerns.

For instance, cross-contamination is a big deal for food processing plants, which require setups that can stop dust particulates from lingering in the air. Another is the aerospace field, where production may involve exotic materials like titanium alloys. Then there are woodworking workshops that generate large amounts of coarse dust, which requires immediate dust clearing.

Workpiece requirements

Along with considering the type of industry the dust collectors will be used in, the workpieces produced in these facilities will also have to be factored in. Large-area mirror-finish workpieces will generate more dust particles, thus may need independent dust collectors to draw the particles close to the source. Additionally, surface quality requirements like nanometer-level precision will indirectly affect the complexity of your dust control needs and thus determine your dust control setup.

Maintenance and Operation Preferences

Expenses for your dust collection system don’t end after placing the order and having it installed in the facility, as it is a long-term investment. You’ll also have to prepare for the recurring costs of keeping the equipment in optimal working condition.

Maintenance Ease

Equipment maintenance can be factored in as early as the design process of the dust collection system. This would include easy access to cleaning, changing filters, or performing repairs with minimal downtime. You can also consider the technical know-how and the size of the facility’s maintenance team, adjusting the dust collector setup to match their capabilities.

Operating Costs

Aside from periodic maintenance costs, there are also regular operating expenses to add into the equation. From energy consumption and filter change frequency to the dust collector’s system lifespan, all these aspects factor into the equipment’s overall design optimization. For instance, energy-efficient fans can be added to the setup to reduce power consumption, while opting for more durable materials can extend the dust collector’s service life.

Automation Requirements

Dust collectors can be modified to handle manual or automated dust collection based on several factors, including dust concentration. If you opt for an automated dust collector, sensors can be integrated into the setup so it can monitor dust concentration in real time. Transitioning to an automated dust collection system can not only reduce manual intervention but can also make air filtration more efficient, especially for small-scale facilities.

Budget and Existing Facilities

Sourcing a dust collection system for a facility requires striking a balance between function and costs. In this section, we’ll crunch some numbers to figure out to determine how to efficiently maintain that balance before signing off on the purchase.

Budget Constraints

There’s always a budget to work on when purchasing any equipment, including industrial dust collectors. As such, it’s a smart move to let the manufacturer know what your budget is as early in the process as possible. Having a set budget, along with your facility’s air filtration needs, will help determine whether to go with a high-end setup or a budget-friendly solution.

Existing Systems

Another point of consideration is the existing setup the facility has before sourcing the industrial dust collector. Some facilities may have a local exhaust ventilation or a previous dust collection system installed, which the current manufacturer should know. Existing setups will require proper evaluation to determine whether integration can be done or a full upgrade is in order.

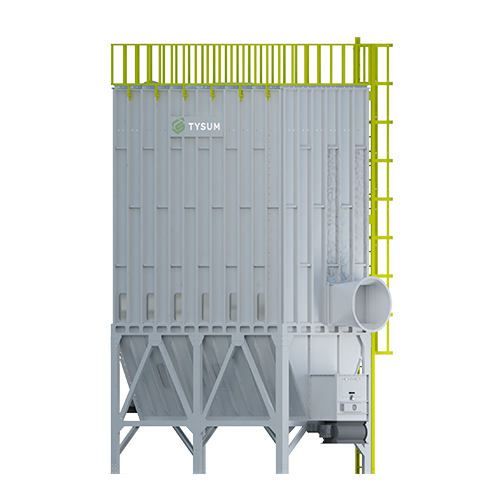

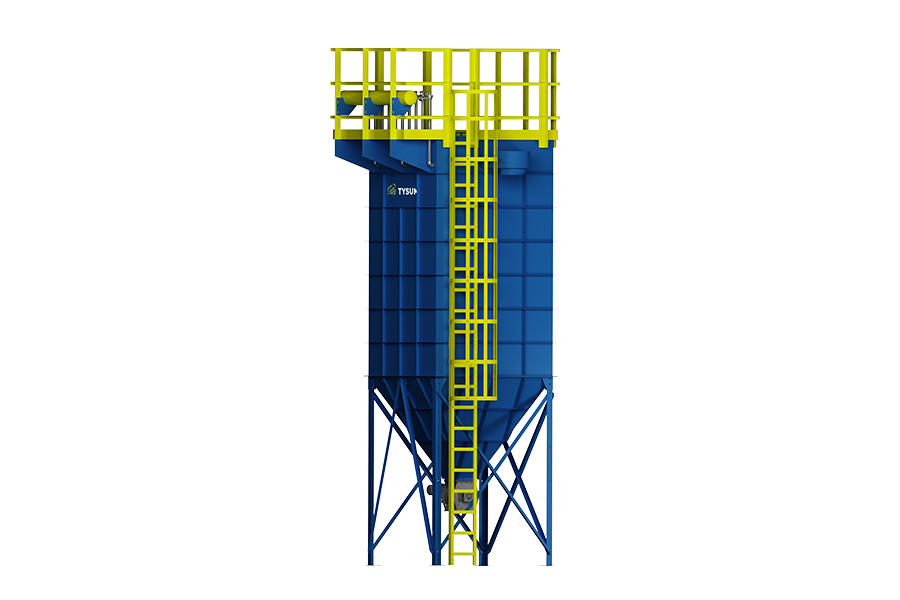

Baghouse Or Cartridge Type Dust Collectors?

Now that you’re ready to purchase a dust collector, you’ll have to know what type your facility needs. There are two main types of dust collectors, namely baghouse and cartridge types, and here are some factors to help you make the right choice.

1. Dust characteristics

Baghouse dust collectors work best for larger particles (>10μm) with high concentration in the air. It’s also better at handling sticky or wet dust particles.

Cartridge dust collectors, on the other hand, are best suited in facilities that deal with fine particles (<2.5μm). This type also works best for low concentrations of dust particles in the factory.

2. Environmental conditions

Cartridge bag collectors are ideal for plants with minimal space allocation, as they typically have a compact design. It’s also good for locations with normal low temperatures, like in pharmaceuticals.

For high-temperature facilities, baghouse bag collectors will fit perfectly with their setup. However, baghouse collectors require a significant space allocation due to their larger size.

3. Budget and Maintenance

If you’re working on a tight budget, cartridge dust filters come at a lower initial cost. Plus, setup and replacement are simpler, though long-term costs will be considerably higher.

On the other hand, baghouse dust filters will cost less in the long term. However, initial sourcing expenses are quite significant, and it has a more complicated maintenance requirement.

4. Regulations and Industry Demands

Baghouse dust filters work for facilities that need to maintain basic emission standards like those in the heavy industry. Conversely, if the facility requires strict high air quality metrics, like the pharmaceutical industry, cartridge bag filters are the key.

Tysum – Leading Dust Collector Supplier in China

When it comes to manufacturing dust collector systems for any industry, no other name comes close to Tysum. We design, manufacture, and support an array of air filtration solutions aimed at elevating air quality and employee health. Our diverse dust collectors are used in over 30 countries, satisfying the needs of more than 500 clients and counting.

Backed by more than two decades of production experience and five world-class facilities around China, we’re experts at turning your ideas into functional air filtration setups. Rely on our talented team and access to the latest technology available to understand your requirements and take your business to the next level.

We take pride in our robust customization process, developing tailor-made dust collectors according to your facility’s specific demands. This is partnered with our meticulous quality control process, conducting numerous inspections and testing to ensure the optimal performance of our dust collectors. All this is capped by a reliable support team that takes care of your concerns throughout the partnership.

Shop for the Best Industrial Dust Collectors

Dust generation occurs in most production plants, and controlling dust particles helps maintain production standards and employee working conditions. Thus, choosing the right industrial dust collector for your business takes a lot of time, effort, and consideration.

This guide has outlined key factors that will help determine which air filtration system will fit your facility’s rigorous demands. From understanding the type of dust particles your factory is creating to the specific type of dust collector to acquire, it’s crucial to check all the boxes before signing on the dotted line.

If you need a dust collector for your plant or are looking into upgrading your current setup, contact the experts at Tysum today. Our decades-long experience in the market and seasoned consultants will take care of all your needs. Get in touch and discover how we can elevate the air quality of your facility.